Featured Maker: Krissie Lagana

Krissie Lagana is a wife, mother, daughter, granddaughter, and soon to be grandmother. Her favorite thing to do is spending time with family and listening to her son play guitar or drums, and is also nuts about baking, and canning. She is originally from Wichita and very proud of being a Wichitan, (she also adds that it isn’t only because she work for the city). She is passionate about her kids, and is sure to be just as crazy for her soon to be grandbaby.

She joined MakeICT after a life altering decision and event. She made a new commitment in life, and states that in an effort to fulfill this commitment she began looking for ways to develop and reinforce new and healthier habits. She concludes that meeting new people and making fun things was a much better “habit” to have. She is proud of the changes she has made thus far and loves the fact that Makerspace has been a big part of her “new ME” journey.

Krissie has worked quite a bit in the woodshop and has completed a tongue drum and a pencil box. She also enjoys quilting, and currently working on more quilts since she now has a long list of people to give quilts to. She also enjoys volunteering time at Makerspace and was part of the past Maker Faire, where she assisted in making canvas bags with the Textile Tribe.

Her advice for those looking to join MakeICT is to “Jump IN with both feet! Come and explore! Have fun and let your curiosity and natural creativity run amok.”

When asked about hidden talents, she confesses that they’re so hidden she hasn’t discovered them yet. So far, she has found that she is pretty good at baking delicious cakes, and when she has the time, patience, and inclination, she can also be a talented decorator.

Another organization she loves is the Harlem Globetrotters, and she had the pleasure of meeting them several years ago. When you see Krissie next time at Makerspace, ask her who “Mighty” is, and she will have fun facts to share with you.

Featured Maker: Brian Norton

Keychains and Luggage Tags by Brian Norton

Field Notes Journal by Brian Norton

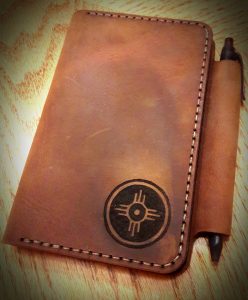

When Brian Norton came to his first Maker Monday to join, it was because he found out the space had a laser that he could use with his leather working. He said he always enjoyed making, building, and tinkering and he was excited to find a place with other creative people that share those same interests.

Brian is originally from Kansas City, MO but having moved to Wichita when he was still in third grade and spending most of his life here, he feels Wichita is home. He has studied Collision Repair and Automotive Refinishing and worked in a body shop for a while, worked retail when the economy went south, returned to school to study business and now working as a General Manager for Damm Music Center where he utilizes his love for music. He finds being able to work around musical instruments every day very rewarding.

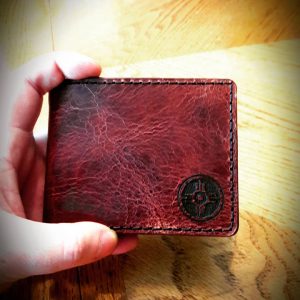

Leather Wallet by Brian Norton

He has done a lot of leather tooling for wallets, guitar straps, and holsters. He has now started doing more laser engraving. He makes leather Wichita Flag keychains, wallets, card wallets, and field note covers. Currently he’s working to get about 100 keychains made up along with some other goods to get them in a few consignment shops in town and hav a table at a craft show. Even though the craft show is not scheduled until fall, he plans to get stuff made as soon as possible before his busy season kicks in and leaves little time for him to get stuff done.

If anyone is thinking of joining MakeICT, Brian advices that they attend a Maker Monday and go through orientation. This is the best way he found to learn about the space and meet people. His other piece of advice for new members is to take as many classes as they can. He states that he is not the kind of person that will just go up and strike up a conversation with someone unless he’s at work, and because of that getting his key form filled out took a while. He started taking classes and meeting people, once he did that he got his form completed quicker.

Money Clip Wallet by Brian Norton

If you want to become more active in the organization, he suggests finding the area of Makerspace you use the most and speaking to the lead of that department. He states that most leads have a lot on their plates and many would welcome having a volunteer to help out. Or, he says, think of a project you made that people thought was cool and teach a class on how to make it. Most importantly, he says, come by the space more often, meet new people, and just help out where you can.

Brian used to play guitar, bass or do vocals in a few different metal bands and even got to go on a short tour with one of those bands. He also plays ukulele as well. When he’s not playing music, he is either working on his “many unfinished projects” or out at the shooting range. He also shoots in a competitive trap league.

Brian Norton

Something that he has not done before but would like to do this year is pottery. He says that he sees all the “cool stuff” coming out of ceramics and he’s decided that he would like to do that too.

September Featured Maker: Michelle LeFavor

In this inaugural entry in our Ceramics Featured Makers series, I’d like everyone to meet @Michelle LeFavor. If you’ve been in the studio the past several months you have undoubtedly seen some of Michelle’s amazing sculpture pieces. Her recent work is remarkably detailed representing the many hours of time she spends on them. Her pieces range from those that look like they’ve jumped right off a coral reef and onto the shelves to whimsical carved bowls and sculptures of nature or fantasy figures. Creativity might just be Michelle’s middle name.

In this inaugural entry in our Ceramics Featured Makers series, I’d like everyone to meet @Michelle LeFavor. If you’ve been in the studio the past several months you have undoubtedly seen some of Michelle’s amazing sculpture pieces. Her recent work is remarkably detailed representing the many hours of time she spends on them. Her pieces range from those that look like they’ve jumped right off a coral reef and onto the shelves to whimsical carved bowls and sculptures of nature or fantasy figures. Creativity might just be Michelle’s middle name.

About Michelle:

Born: Bellingham, WA – right near the Canadian border

Started in Ceramics: Was taking a metaphysics class and the instructor brought in a chunk of clay and said “make a sacred object”. Having never done anything with ceramics before, she dove right in and made a small statue of the Goddess of Willendorf. She just seemed to have a knack for it! Took some classes at Butler and WSU and really liked it. And she hasn’t stopped yet.

Why Ceramics: It’s therapeutic, whether it turns out or not! Michelle says: “This is my church. It’s the closest I can get to God, spirituality, or zen. When I’m creating, it’s when I get into my zone. I’ve always been creative and always wanted to be an artist when I grew up. I have this uncontrollable compulsion to make things.”

Biggest Ceramics Challenge: Glazing!

Hobbies: Ceramics, travel, drawing, black ink portraits.

If She Had One Wish: “I’d want to live in the mountains in a little cabin, with my dogs, and a little ceramics studio.”

Please say howdy to Michelle the next time you see her!

Thank you Patrick Hutchison for contributing this post

Featured Maker: Scott Sullivan

Scott Sullivan makes the most of his monthly membership dues. He joined MakeICT to have access to a woodshop, metal

shop and pottery studio, but when I first met Scott, he was hanging out with the Textile Tribe repurposing old shirts into aprons. He definitely utilizes the most of what Makerspace has to offer.

Scott was born in Seoul, Korea. He describes growing up as “not quite an ‘army brat’ but close”, moving to a new location every 3 to 4 years. He caught the ceramics bug while an exchange student at Kansai University of Foreign Studies in Osaka, Japan. He has a lot of ideas he would like to try when it comes to pottery, currently working on making a bird bath for his front yard. He states that not having thrown anything that large, he finds this project quite a challenge. Another project he is working on is designing a metal candle holder to be cut out with Plasma CNC.

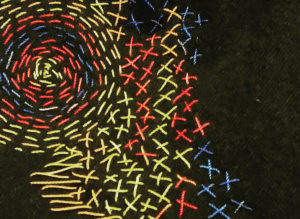

Scott considers himself a “general all around crafter”. He knits, crochets, weaves, embroiders, makes brooms, does leather work, gardens, and sews. He is the treasurer of the CSMA (Central States Metal Artisans) blacksmith organization. And if you think there’s not enough hours in a day, he also studies foreign languages, already having studied French, German, Chinese, Arabic, Irish, Russian and Icelandic.

When asked to ponder deeper on the reason they make manhole covers round, he responds “Manhole covers are round because manholes are round. Manholes are round because manhole workers are round.”

Thank you Jenni Alonso for contributing this post.

Featured Maker: Dominic Canare

Dominic originates from Derby, Kansas. He is a collector of degrees and is currently working on finishing a PhD in Human Factors Psychology and Human Computer Interaction from Wichita State University. Except for planning his upcoming nuptials, obtaining his PhD is his most current passion.

Dominic originates from Derby, Kansas. He is a collector of degrees and is currently working on finishing a PhD in Human Factors Psychology and Human Computer Interaction from Wichita State University. Except for planning his upcoming nuptials, obtaining his PhD is his most current passion.

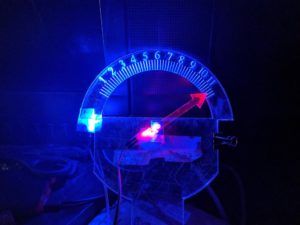

Some of Dominic’s current projects include research in brain plasticity, perceptual and motor learning, and helping develop a high-fidelity driving simulator to investigate trust in automation and aging effects on driving. Driving most of his projects is the motivation to improve the human experience.

Dominic wants to specifically encourage people to volunteer for MakeICT Outreach events. He proclaims that it is actually easier and way more fun that it seems like it could be. But above all of the good stuff that happens at Makerspace i.e. collaborating and socializing, the best times for him involve working on his projects in his “zen-place” which consists of just being surrounded by equally productive individuals.

Outside of school, work, and volunteerism, Dominic has also dabbled in some professional modeling, he claims to have been a model for a balloon company, and has submitted a photo as proof. He is also a protector and provider of two domesticated cats, and promised to be wed to one domesticated woman.

Outside of school, work, and volunteerism, Dominic has also dabbled in some professional modeling, he claims to have been a model for a balloon company, and has submitted a photo as proof. He is also a protector and provider of two domesticated cats, and promised to be wed to one domesticated woman.

Thank you Jenni Alonso for contributing this post.

Featured Maker: Allan Bacon

One of the most wonderful things about MakeICT is the wide array of experience levels in our makerspace. We have brand new makers who’ve gone from knowing nothing to making art with a plasma cutter in six months. We have highly experienced makers who’ve been creating great things since before MakeICT was around. Allan Bacon is an experienced woodworker whose tables caught our eye, so I sat down to talk with him about how he got started and where he finds inspiration.

Allan has been woodworking for 22 years. He originally started in to make martial arts weapons when he wasn’t satisfied with what was commercially available, and diversified over time into different wooden styles. A few years ago he saw a live edge table and admired the juxtaposition with the natural edge and the glossy, smooth top. He had just retired from the aircraft industry and had time for bigger projects.

Inspired by pacific northwest artists like Greg Klassen and George Nakashima, live edge tables retain the outer bark of a slab of wood. Some have natural holes to fill in, other tables are made by splitting the slab in half lengthwise so the bark edges are turned to face each other. Allan has used different techniques to fill in the center: resin fill, acrylic or glass tops, LED lights, even phosphorous powder mixed in to casting to glow in the dark.

Allan gets his supplies from Richard’s Wood Shop in Kechi, Cook’s Woods online, Intermountain wood, and friends around the Wichita area. For one table he used an antique singer sewing base. There was a lot to learn in taking the treadle table apart, cleaning it, and re-assembling the cast iron parts to work together just as they had since the 1890s.

Like many of our members, Allan has his own shop at home but he joined MakeICT in its first few years because we had some tools he did not have, like a 15″ planer and CNC shopbot router.

He says he recommends it to people all the time and has talked with plenty of woodworkers in other cities who are jealous of what we offer for $25 a month. “For someone who would like to get started in wood, the MakeICT project classes are a great intro to the world of woodworking. The projects use several of the machines in the shop and the instructor is right there to help along the way,” he says, “Plus you will meet other people with similar interests, so it’s a good networking opportunity. The people there are usually more than willing to answer questions and are glad to show you their projects.”

“For me, MakeICT offers access to machinery that I couldn’t begin to afford. And with a fob/card you have 24/7 access. You don’t have to schedule around “Open” hours. Plus there are machines that I’ve thought would be interesting to learn, but had nowhere to do so. How does the average person get access to a laser cutter, much less learn how to use it? Or a CNC plasma table? Or a 4’ by 8’ ShopBot? Only at MakeICT.”

Featured Maker: Malissa Long

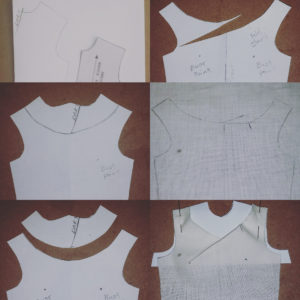

Our February featured maker is Malissa Long: Fiber artist, fashion designer, sewn product developer, pattern maker, technical designer, and finally MakeICT board member and textiles area lead. She has taught classes in sewing, dying, printing and lots of other forms of art. Malissa moved to Wichita from Austin in July 2015.

Our February featured maker is Malissa Long: Fiber artist, fashion designer, sewn product developer, pattern maker, technical designer, and finally MakeICT board member and textiles area lead. She has taught classes in sewing, dying, printing and lots of other forms of art. Malissa moved to Wichita from Austin in July 2015.

“I moved to Austin shortly after the new airport opened and the Greater Austin Area had 500,000 people. I moved to Wichita shortly after the new airport opened and the Wichita Metropolitan Area had 500,000. Wichita reminds me a lot of those early days in Austin. If great things could happen there I can’t wait for what’s in store here.”

Malissa is seen at MakeICT a lot but one great time to catch her is at Textile Tribe on the second Sunday of each month in the afternoon. Textile Tribe is a casual come-and-go event where anyone can bring in Unfinished Fiber Objects (UFOs) to work and collaborate on.

“I love MakeICT for the community it creates, the knowledge that is shared, the creativity it invites. The fact I know nothing about electronics, yet my son is obsessed at the moment and we can take classes and learn together. That he can come in and ask what a flame diode is and some one will take the time to explain it to him in terms that a 9-year-old can understand.”

Malissa brings a great depth of knowledge in the world of fiber arts and is always trying something new. “I discovered Boro recently, it basically simple running stitches used to mend or repair thin spots in fabric by adding a patch. I’m actually using the stitches to surface embellish a dress I’m making out of old jeans.” She’s being sewing since childhood, with two sewing machines by the age of nine and a family of makers who sewed her clothes.

Her class called “Know Your Sewing Machine” invites curious beginners to bring in their own machines to gain the technical background to run their machines properly. “Driving a sewing machine is like being in stop and go traffic,” she says, “it’s not an open highway where you maintain speed. You Pump the foot pedal, let the machine pull the fabric, and use your hands to lightly guide the fabric.” I know it a lot to remember even I forget sometimes.

Keep up with Malissa and view more of her creations at mlwear.com or on instagram @mlssfshn.

January Featured Monthly Maker David Springs

Cypress Table by David Springs

MakeICT’s Featured Maker for this month is David Springs. David rents space in one of our front cubicles. “Our makerspace is like Disneyland for anyone who is creative,” he says. “It’s a place that enables folks who like to make things to actually make them!”

Being a maker is a big part of his life. Among other things, to him MakeICT means access to top-notch equipment, making dreams into reality. “It means a nice, warm wood shop instead of a dimly-lit, freezing garage, equipped with a contractor saw on a rickety stand. It means ideas and advice from other members when I’m trying to solve a problem.”

A hard drive jukebox, by David Springs

David is often at the space working on the many projects he has in development. “There’s nothing quite like taking an idea that’s in your head and turning it into an object that you can hold in your hands and share with others. I’ve always got about ten projects in various stages of development. Every time I come up with some idea, I write it down and put it on a plastic bin in my studio. Then I start collecting the materials I need, adding them to the bins as I get them. Eventually I have enough stuff to actually start building.”

Some of the projects you might have seen him working on around the makerspace:

- A talking Darth Vader/jukebox/night light

- Self-balancing cane

- Street art space paintings, including his entire vehicle

- A full-size old school arcade game cabinet

- Clocks out of anything – parking meters, skeletons, light up ping pong balls, analog panel meters.

- Intel Edison-powered punching/kicking dummy “for a bunch of little kids who will one day be Taekwondo black belts”

Last year while driving through western Kansas, David was inspired by the many metal whirligig-type sculptures that turn our state’s wind into moving art. He designed and completed his own gear-driven model of Godzilla eating Tokyo. “This project is probably a one-off,” David says.

And just like every project, he learned new things while working on it. This time, he learned “that sometimes things don’t work in quite the way you envision them in your head!” David used many of the resources available at MakeICT to put the whirligig together. “I’ve used the wood shop for the structure, the laser for Godzilla and the buildings of Tokyo, one of our 3D printers for some gearing and adapters, the electronics lab to give the buildings of Tokyo and Godzilla’s eyes LED lighting and sound.”

David’s Godzilla Whirligig

Thanks to Gordon Murray for contributing to this post.

Featured Maker: Tom McGuire

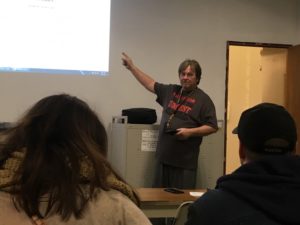

Tom McGuire, MakeICT’s makerspace director.

This month, our Makerspace Program Director, Tom McGuire, is MakeICT ‘s Featured Maker. We asked him about MakeICT and his favorite personal project.

“I don’t get a chance to really work on it too much, but the foam cutting machine is my primary project right now. It can take a drawing that you make on a computer and cut it out of 1/4 inch thick Styrofoam sheets,” McGuire said.

He has six machines now and is working on two more.

McGuire started the foam cutter back in 2008 when he was asked for help working with foam. The project continued to evolve into other projects during the years since.

He has used the resources at MakeICT to help him further refine the design and function of the foam cutter.

Tom working on his CNC foam cutter.

“I’m still working on it and MakeICT is a big part of the progress, both with software development and seeing how other people like to use the thing.” McGuire added, “Dominic is working with me to make the software better. It’s looking good.”

McGuire says that giving other makers advice about starting their own foam cutting projects has been problematic.

“It’s always been too complicated to expect other people to try to do. Someday I hope to tell them to go to Instructables.com and learn everything they want to know to make one. That’s still in the works, but the advances we are making on it will make that possible.”

McGuire has been tinkering with things since he was very young.

“I never did mess with cars too much, but I did get hooked into electronics and made a career out of it. Now I work at WSU showing students how to learn and make things.”

McGuire is also thinking about future projects.

Project wall at MakeICT featuring various foam objects made on Tom’s machine.

“When I retire I want to build a machine that makes some of the strangest and most beautiful music.”

When asked about MakeICT, McGuire says, “It’s always fun to be a part of something that is growing. I make friends there that I never knew existed before. It’s like a big flower pot full of really good dirt.”